AP&C’s history of industrial roots, experienced technical staff, and our attention to details provide our customers peace of mind when purchasing an AP&C remanufactured Motor-Generator. Every AP&C remanufactured Frequency Converter undergoes the thorough remanufacturing process shown below, and is rigorously tested to insure it meets rating specifications.

Preliminary Review (your existing Motor-Generator): AP&C engineers will make a review of your existing Motor-Generator, using photos you provide of the inside and outside, and by asking you specific questions to help determine the general condition of the equipment. We’ll determine if your existing Motor-Generator is a good candidate for our remanufacturing process, refurbishment or repair. In some cases, AP&C can offer a trade-in value for your motor-generator that can be used towards the purchase of any frequency converter from AP&C.

Incoming System Inspection: Each unit is subjected to a thorough physical and visual inspection.

Incoming System Test: Electrical and mechanical diagnostic, functional & load tests are performed.

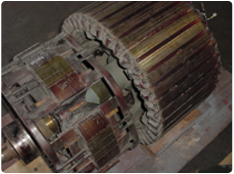

Disassemble / Test: The Unit is disassembled and further tests are performed as necessary.

Components: All components are removed, cleaned, tested and inventoried. Any components found to be outside acceptable limits during testing are repaired or replaced. Existing control-wiring harnesses are replaced with all-new electrical control circuits.

Windings: All electrical power windings are tested, cleaned and spray reinsulated. Faulty power windings are replaced.

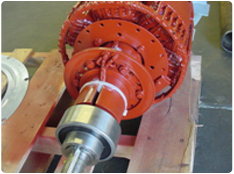

Surfaces All metal surfaces are cleaned, treated for corrosion, straightened, primed and painted.

Bearings: All bearings are replaced with high quality bearings.

Drive Belts: All drive belts are replaced.

Upgrades: The unit is checked & upgrades installed as needed or as requested by the Customer. These upgrades may include any electrical or mechanical feature that affects operation functionality or safety.

Outgoing Test: Quality Assurance checks, calibration, functional and load testing are performed to insure specifications are met. Load test results are recorded. The unit is detailed, including any labeling required.

Packaging: The completed unit is plastic wrapped and fastened to a custom heavy-duty pallet.